Why Nike Shoe Manufacturing Remains A Challenge For Robots

Table of Contents

The Dexterity and Precision Hurdle

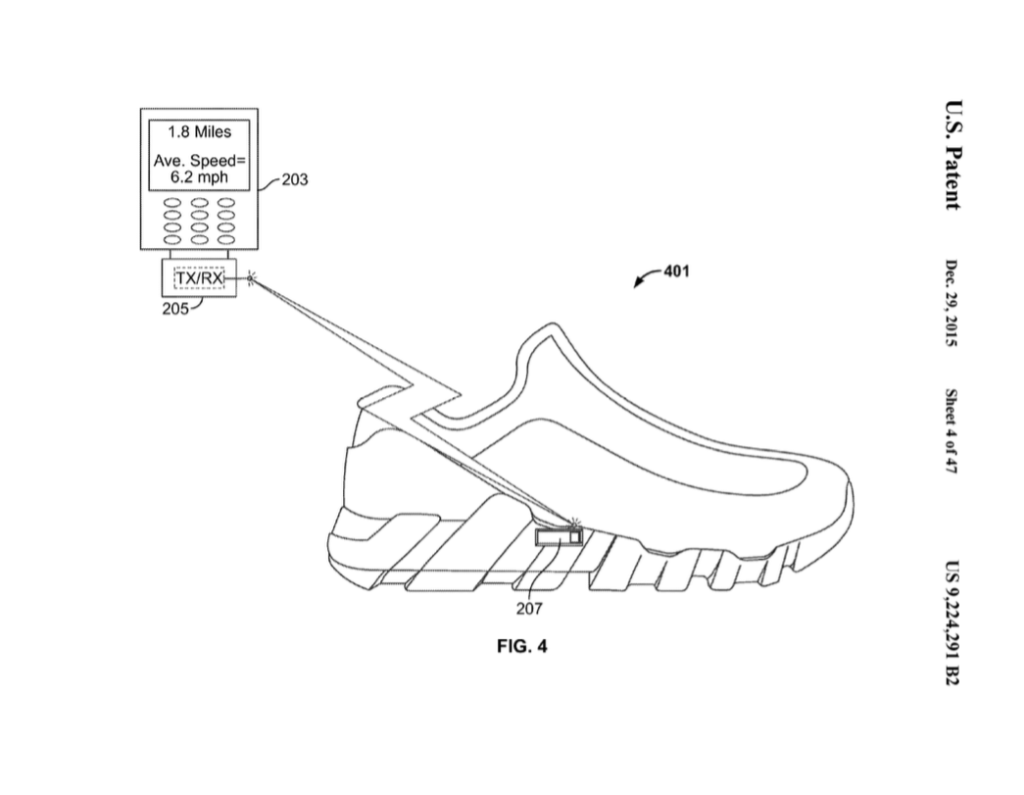

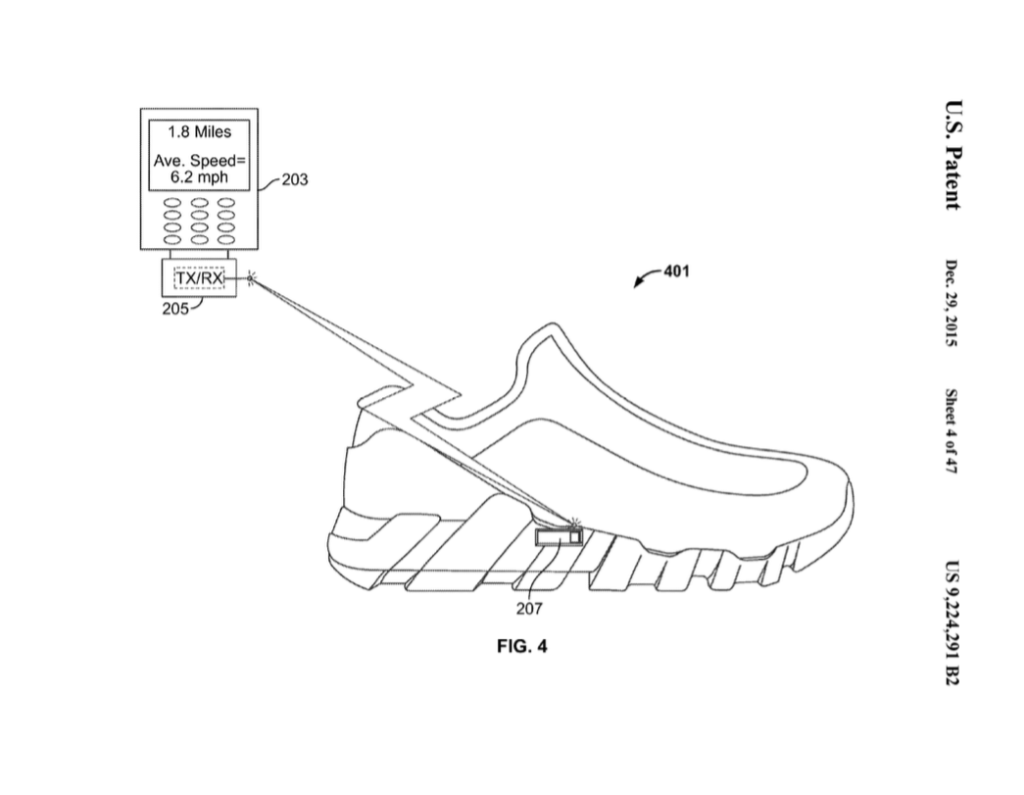

The creation of a Nike shoe is a surprisingly complex process, demanding a high degree of dexterity and precision that current robotic technology struggles to replicate.

Complex Assembly Processes

Assembling a Nike shoe involves a multitude of intricate steps. Consider the following:

- Attaching the Swoosh: Precise placement and alignment of the iconic Nike swoosh requires fine motor skills and visual acuity far beyond the capabilities of many current robots.

- Stitching and Gluing: The consistent application of glue and the precise stitching of various materials demand a level of dexterity and control that robots are still developing.

- Midsole Assembly: The careful alignment and attachment of the midsole, a crucial component for comfort and support, requires high-precision robotic manipulation.

These delicate manipulations, combined with the variations in design across Nike's vast product line, present significant obstacles for robotic automation. Current robots often lack the adaptability and finesse to consistently perform these tasks with the speed and accuracy of human workers.

Material Handling Challenges

Nike shoes utilize a wide array of materials, each presenting unique challenges for robotic handling:

- Leather: The varying flexibility and texture of leather make it difficult for robotic grippers to maintain a consistent grip without causing damage.

- Mesh: The delicate nature of mesh fabrics requires careful handling to prevent tearing or stretching during the assembly process.

- Synthetics: Different synthetic materials have varying properties, requiring robots to adapt their gripping force and manipulation techniques.

Successfully automating these processes requires the development of adaptable robotic grippers and sophisticated sensor systems capable of recognizing and responding to the different properties of each material.

Adaptability and Customization Limitations

Nike's success is built upon its diverse product line, catering to a wide range of styles, sizes, and customer preferences. This diversity presents a significant hurdle for robotic automation.

Varied Shoe Styles and Sizes

The sheer scale of Nike's product variations poses a major challenge:

- Different Shoe Designs: Each shoe model, from running shoes to basketball shoes, may require unique assembly processes and robot reprogramming. This translates to significant time and cost implications.

- Size Variations: The wide range of sizes, from children's to adult's, necessitates adaptability in robotic systems, demanding complex adjustments to assembly procedures.

Reprogramming robots for each new style or size is impractical on a large scale, highlighting the need for more flexible and adaptable robotic systems.

Customization and Personalization

The growing trend of personalized sneakers further complicates the automation equation:

- Bespoke Designs: The ability to create unique, custom designs requires highly adaptable robotic systems capable of handling variations in material, color, and construction.

- On-Demand Manufacturing: The shift towards on-demand manufacturing, where shoes are produced only when ordered, demands flexible and responsive robotic systems that can quickly adapt to changing demands.

Integrating customization and personalization into existing robotic manufacturing lines is a significant technological hurdle that requires significant advancements in artificial intelligence and robotic control systems.

Cost and Economic Considerations

Implementing robotic automation in shoe manufacturing requires substantial investment, raising critical economic questions.

High Initial Investment

The cost of implementing advanced robotics in shoe manufacturing is considerable:

- Robot Purchase and Maintenance: The cost of purchasing and maintaining advanced robotic systems is substantial, requiring a significant initial capital investment.

- Programming and Integration: Integrating new robotic systems into existing production lines requires significant programming and engineering expertise, further increasing costs.

Return on Investment (ROI)

The economic viability of robotic automation in shoe manufacturing depends heavily on several factors:

- Speed and Accuracy: Currently, robots may not match the speed and accuracy of skilled human workers in certain tasks, potentially offsetting cost savings in the short term.

- Error Rates: While robots can improve consistency, initial error rates might lead to higher material waste and production downtime until optimal performance is achieved. This needs to be factored into ROI calculations.

While the long-term benefits of robotic automation are potentially significant, the high initial investment and potential short-term limitations present considerable economic challenges.

The Future of Robotics in Nike Shoe Manufacturing

The challenges facing robotic automation in Nike shoe manufacturing – dexterity, adaptability, and cost – are significant. However, ongoing advancements in robotics offer reasons for optimism. AI-powered systems, advanced sensor technologies, and improved robotic dexterity are gradually overcoming these hurdles. While complete robotic automation remains a significant challenge, ongoing research and development continue to push the boundaries. Continue exploring the complexities of Nike shoe manufacturing and robotics to understand the ongoing evolution of this fascinating field.

Featured Posts

-

Secret Service Closes White House Cocaine Investigation

Apr 22, 2025

Secret Service Closes White House Cocaine Investigation

Apr 22, 2025 -

China And Indonesia Deepen Security Cooperation

Apr 22, 2025

China And Indonesia Deepen Security Cooperation

Apr 22, 2025 -

Swedens Tanks Finlands Troops A Pan Nordic Defense Force

Apr 22, 2025

Swedens Tanks Finlands Troops A Pan Nordic Defense Force

Apr 22, 2025 -

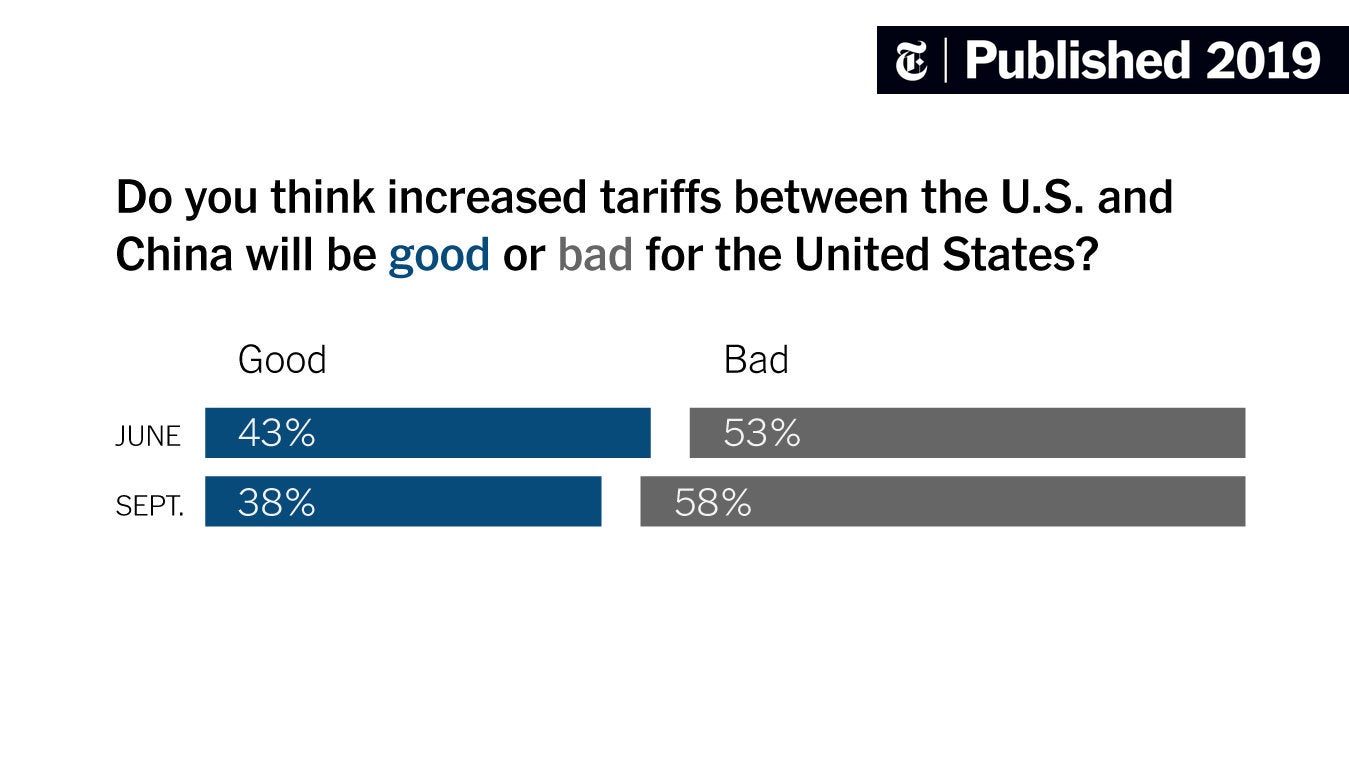

Analyzing The Long Term Effects Of Trumps Trade Strategies On Us Financial Strength

Apr 22, 2025

Analyzing The Long Term Effects Of Trumps Trade Strategies On Us Financial Strength

Apr 22, 2025 -

Over The Counter Birth Control A New Era Of Reproductive Healthcare

Apr 22, 2025

Over The Counter Birth Control A New Era Of Reproductive Healthcare

Apr 22, 2025